Business sustainability requires the application of agile processes at the project and programme level: integrated digital processes lead to better connectivity between employees and collaborative development – iterate faster and achieve optimised solutions.

Since the term Industry 4.0 was coined a decade ago, we’ve seen a steady drive to apply its principle concepts across industrial sectors. Over this same period, the use of cloud-based technologies has soared, with 99% of enterprises benefiting from the adoption of a public cloud. Simulation has become even more ubiquitous, and data analytics, empowered by cloud storage and computation, is king.

The view from the C-suite might not reflect the day-to-day challenges technical teams face with the technologies they’re using. In many firms, engineering project management processes have not been updated for digital integration, but instead a paper-based system is simply mapped across. This means system data often does not automatically update, field data is not readily retrievable and engineering analysis – and therefore design – relies on assumptions and hypotheses instead of using field data to tune physics-based models or design phenomenological models.

Cygnas Solutions has extensive experience in engineering and product development in the energy sector. From an Industry 4.0 perspective, we’ve seen that business sustainability requires the application of agile processes at the project and programme level: integrated digital processes leading to better connectivity between employees and collaborative development. The time and cost savings add up, providing a shift from high-latency, high-error processes to low-latency, low-error processes. Put in the engineering context, it’s the capacity to iterate faster to achieve an optimised solution. This is more than running ever more simulations with cloud computing facilities taking the strain, as this cheap computing power comes at an increasing environmental cost. Enriching the data through a smart digital reality provides insights and efficiency gains crucial for a sustainable future.

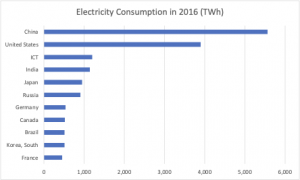

The near ubiquitous cloud computing power that is thrown at problems uses energy and generates heat. The storage of data that cannot be used, likewise uses energy and generates heat. Globally, the world’s information communications technology (ICT) systems are estimated to be the third largest consumer of energy, following only China and the United States.[2] [3].

Hexagon is taking this challenge head-on as was clear in the keynote speech given by Hexagon’s CEO Ola Rollén, in which he highlighted the importance of the smart digital reality implementation and automation in reducing wastage and human error.

Figure 1 Global ICT electricity consumption relative to 10 largest countries for 2016 [2] [3]

References:

[1] The State of the Public Cloud in the Enterprise, Contino Research Report, 2020

[2] CIA World Fact Book, Country Comparisons Electricity – Consumption, CIA (data retrieved 13/06/2022)

[3] A. Andrae, A., Edler, T., On global electricity usage of communication technology: trends to 2030, Challenges, 6 (2015), p. 117

Molitch-Hou, M., The Cloud Paradox: Less Energy Used, More Energy Wasted, Oct 2019, retrieved 14 June 2022 (https://www.engineering.com/story/the-cloud-paradox-less-energy-used-more-energy-wasted?postID=24406)